Crane Wheels

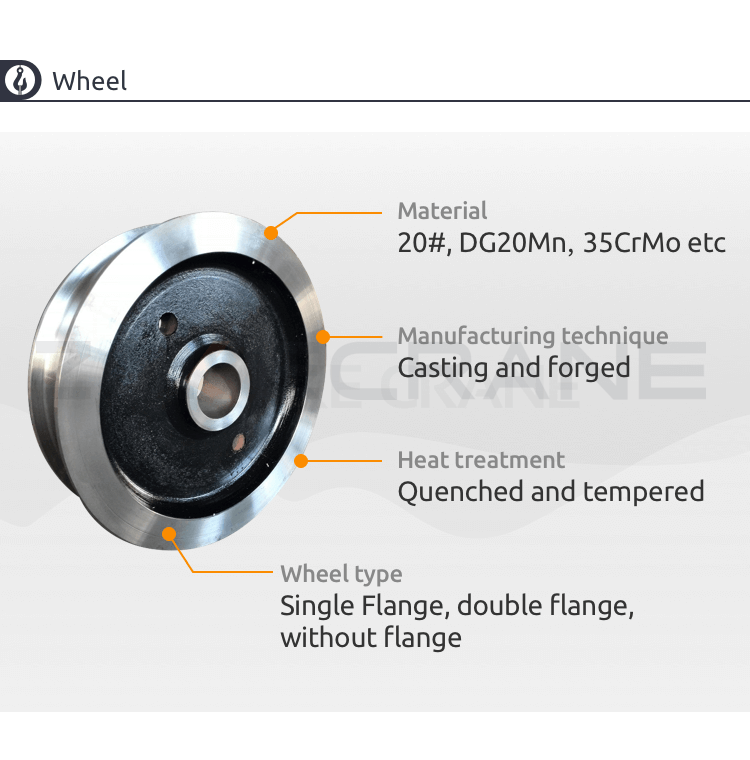

- Material: 20#, DG20Mn,35CrMo etc.

- Manufacturing technique: Casting and forged

- Heat treatment: Quenched and tempered

Introduction

The wheel is an important part of the crane, which runs on the track and bears the dead weight and load of the crane. Crane wheel material should have high strength, high hardness and good wear resistance.

Crane wheel is divided into single rim wheel, double rim wheel and missing wheel. Single flange wheel is mainly used in gantry crane under 5t, double beam gantry bridge crane trolley running mechanism; Double rim wheel is mainly used in gantry crane, double beam bridge gantry crane, crane operation mechanism, casting crane operation mechanism, electric flat car, platform car group, ship unload, shipyard, port machine, coal unload, stacking and taking machine, quay bridge machine and so on.

According to the characteristics of driving, the wheel tread is required to have high hardness, and a certain depth of hardened layer and transition layer (depth> 10mm, hardness HRC40-48) to improve the bearing capacity, wear resistance and contact fatigue performance. At the same time, the matrix structure is required to have good comprehensive mechanical properties and good structural state, and the hardness should be HBS187 ~ 229, so that it has high toughness, improve impact resistance and crack resistance.

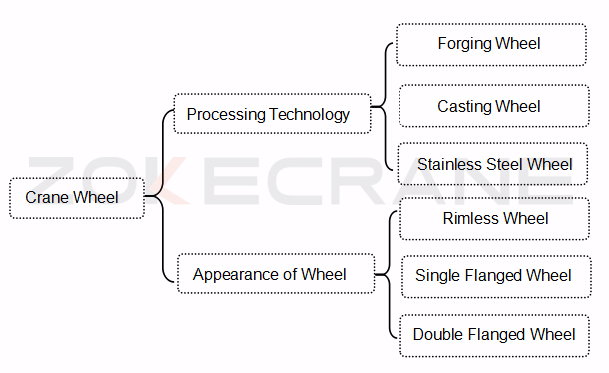

Types

Details

| Type: | Forging Wheel/Casting Wheel |

| Application: | Crane,trolley,transfer car,heavy duty industry,Port crane,Steel factory etc |

| Material: | 4140/SCM440/42CrMo,ssw-QIR/65#steel,65Mn,50SiMn,QT800 |

| Dimension: | Φ250, Φ350, Φ400, Φ500, Φ600, Φ700, Φ800, Φ 1000, Φ 1200 or as your require |

| Process: | Forging/Casting |

| Quality Control: | UT,MT,RT,PT,chemical composition test,mechanical property test,etc. |

| Heat Treatment: | Quenching and Tempering |

| Quenching Depth: | no less than 20mm |

| Coating: | Black Oxide+Rust-proof oil |

| Inspection: | Besides our in-house inspecion, you could also choose a third party inspection |

| Standard: | ASTM, ASME, DIN, JIS, ISO, BS, API, EN,GOST,etc |

| Certificate: |

1, Raw material certificate(material chemical compositon) 2, Heat treatment sheet report 3, Dimension inspection report 4, UT/MT test report |

| Packing: | Seaworthy plywood packaged on steel pallets or as customer's request |

| Delivery Date: | 15~30 working days |

| Competitive Advantage: | Quality control and management to the whole produce process, including ingot smelting,forging, heat treatment, machining and strictly final inspection prior to delivery. |

Size

| D(Wheel width) | D1 | B(Wheel diameter) | B1 |

| 100 | 130 | 80~100 | 95~100 |

| 125 | 140 | 80~100 | 95~100 |

| 160 | 190 | 90~100 | 95~100 |

| 200 | 230 | 95~100 | 95~100 |

| 250 | 280 | 95~140 | 95~140 |

| 315 | 350 | 95~210 | 95~210 |

| 400 | 440 | 105~210 | 105~210 |

| 500 | 540 | 105~210 | 105~210 |

| 630 | 680 | 120~210 | 120~210 |

| 710 | 760 | 140~210 | 140~210 |

| 800 | 850 | 140~210 | 140~210 |

| 900 | 950 | 145~220 | 140~220 |

| 1000 | 1060 | 145~220 | 140~220 |

| (1250) | 1310 | 145~220 | 140~220 |

Catalog

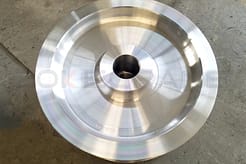

| Casting Wheel |

Material: cast steel or cast iron; Loading capacity:1-300 tons, can be customized. |

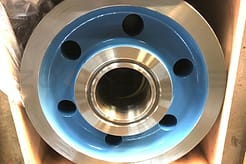

| Forged wheel | The material generally is 50SiMn and 42CrMo.The processing method is Casting or Forging. |

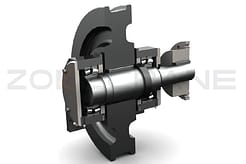

| Wheel block | These wheel assembly are technically advanced and successfully used in different industries. |

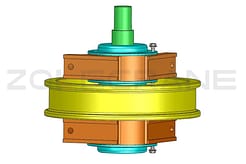

| DRS Wheel Block |

Safe, simple and convenient; Large wheel load; Good braking performance. |

Advantage

- Reduce maintenance cost of your wheels and wheel assemblies

- Improve the life of your rail

- Provide an additional 40% load carrying capability over rim toughened wheels

- Delivery in 6-8 weeks, less when required

Features

- Manufactured from fine gain, fully killed, vacuum degassed forged medium carbon steel

- Heat treated using our in house processes to provide a uniform contour hardness in the tread and inner flange wear surfaces, while maintaining a ductile core to resist shock loads

- Resistant to flange fracture or wear

- Designed to resist pitting and spalling

Application

ZOKE industry wheel are technically advanced and successfully used in different industries like Steel Plant, Rolling Mill, Cement Plant, Fertilizer Plant, Paper Mill, Chemical Industries etc. to cart heavy lode.

Typical applications: Overhead cranes Gantry and portal cranes Transfer cars.

Need Help? Contact our support team today !

If you have any questions or free quotes for the product, we will reply within 24 hours! please do not hesitate.