Overhead cranes are generally made up of a bridge (also known as a large car). Lifting mechanism, trolley, trolley moving mechanism, manipulation room, trolley conductive device (auxiliary sliding line), crane total power conductive device (main sliding line) and other parts.

Bridges

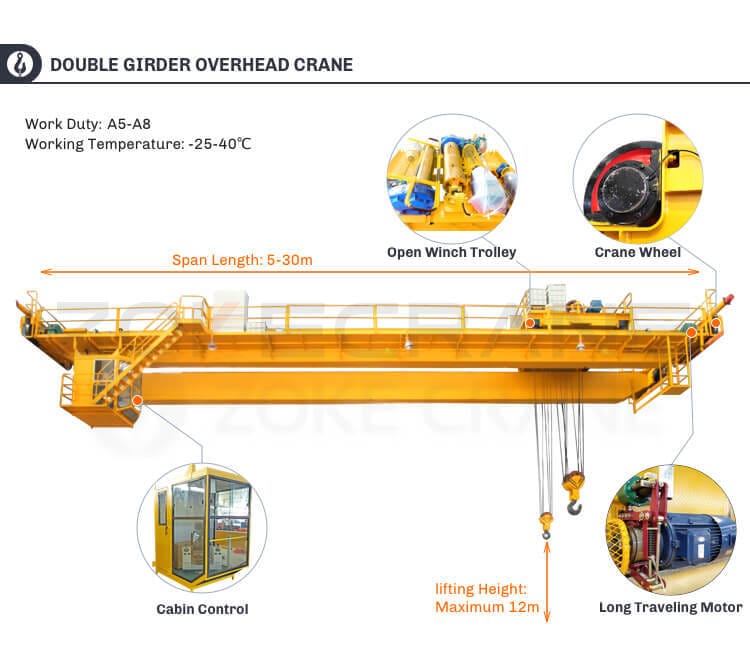

The bridge frame is the basic component of the overhead crane, it consists of the main beam, end beam, walking platform and other parts. The main girder span over the span, there are box-shaped, analysis frame, web, round tube and other structural forms. The main beam is connected to the end beam at both ends and has a walkway on the outside of the two main beams with safety rails. On one side of the cab the platform is equipped with a large car moving mechanism, and on the other side the platform is equipped with a device for supplying power to the electrical equipment of the car, i.e. an auxiliary slide line. A guide rail is laid above the main beam for the trolley to move. The entire overhead travelling crane is dragged by the trolley moving mechanism and moves along the rails in the length of the workshop.

Large vehicle transfer mechanism

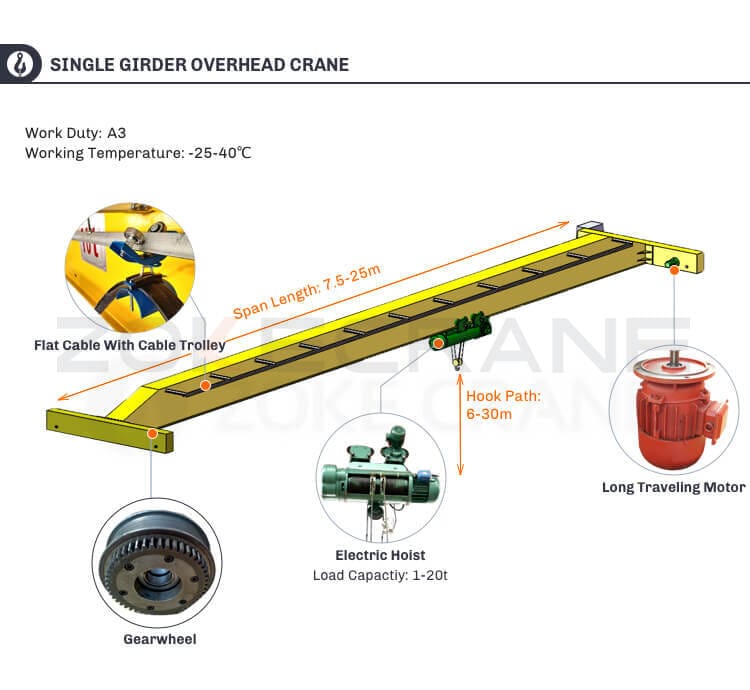

The car shifting mechanism consists of the car dragging motor, drive shaft, reducer, wheels and brakes, etc. The driving methods are centralised and separately driven.

Trolley transfer mechanism

The trolleys are placed on the bridge rails and can be moved in the direction of the width of the workshop. The trolley is mainly made of welded steel plates and consists of a trolley frame with a trolley moving mechanism and a lifting mechanism.

The trolley moving mechanism consists of a trolley motor, brake, coupling, reducer and wheels. The trolley motor drives the trolley active wheel via the reducer and drags the trolley along the guide rails, which is driven by an electric motor as the trolley active wheels are close together.

There are two forms of transmission for the trolley moving mechanism: one is the gearbox in the middle of the two active wheels; the other is the gearbox mounted on one side of the trolley. The reduction gearbox is installed in the middle of the two active wheels, so that the drive shaft is subjected to a more uniform torque; the reduction gearbox is installed on the side of the trolley, so that the installation and maintenance is more convenient.

Lifting agencies

The hoisting mechanism consists of a hoisting motor, reducer, reel and brake. The lifting motor is connected to the reducer by coupling and brake wheel, the output shaft of the reducer is connected to the winding reel of steel wire rope, the other end of the steel wire rope is equipped with hook, when the reel is rotating, the hook will rise or fall with the winding or release of the steel wire rope on the reel. For cranes with a lifting capacity of 15t and above, two sets of lifting mechanisms are available, namely the main hook and the secondary hook.

From this, it can be seen that the weight on the hook with the rotation of the reel to obtain up and down movement; with the trolley in the workshop width direction to obtain left and right movement, and can be with the large car in the workshop length direction to do back and forth movement. In this way it is possible to realise the movement of the weight in the vertical, lateral and longitudinal directions, to move the weight to any position in the workshop and to complete the task of lifting and transporting it.

Control room

The control room is the cabin where the crane is operated, also known as the cab. In the operating room, there are controls for the large and small crane transfer mechanism, controls for the hoisting mechanism and protection devices for the crane.

The control room is generally fixed at one end of the main beam, but there are a few that are mounted underneath the trolley and move with the trolley. There is a hatch at the top of the operating room leading to the platform for the maintenance personnel to get on and off the large and small car mechanical and electrical equipment.

Henan Zoke Crane Co., Ltd. is a professional crane manufacturer.The company has advanced production equipment and strong technical force.Provide product design, manufacturing, sales, installation, maintenance, technical consultation and services.If you have any questions, you can contact us, 24 hours professional customer service online to answer you.