Lifting machinery wheels are used to support the weight of the crane and the weight of the crane itself, and guide the crane along the track running that is the role of support and guidance, so the wheel should be one of the important parts of lifting machinery. But our lifting machinery inspectors in the installation of lifting machinery supervision and inspection process found that lifting machinery wheels generally have low wheel hardness (Brinell hardness HB 60 to 80), in the use of the process sometimes appears lifting machinery wheel rim was torn broken, resulting in lifting machinery car walking mechanism or trolley walking mechanism in the use of walking mechanism derailment of major safety accidents.

The introduction of lifting machinery wheels

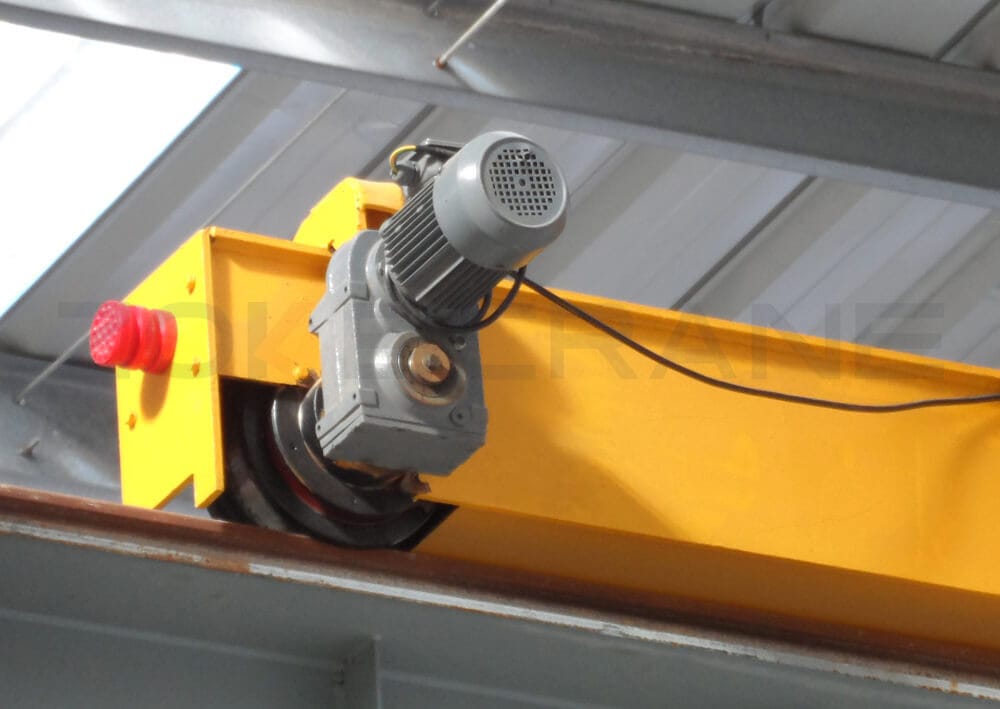

Wheel is an important component of the crane and crane trolley operating mechanism, lifting machinery wheels in accordance with the form of the rim can be divided into three types. Double rim wheels, the rim of the operation of lifting machinery has a guiding and prevent derailment role. Double rim wheels are mainly used for bridge, portal, gantry crane trolley walking wheels. If the diameter of the trolley wheels is greater than 500mm, the trolley wheels also need to use double rim wheels. Single rim wheels are mostly used for wheel diameter less than 500mm crane trolley running wheels, due to the small span of the trolley frame, the stiffness is relatively strong in the use of the process is not easy to appear wheel derailment phenomenon. In the installation, the end with the rim should be arranged in the outer side of the gauge. Rimless wheels, lifting machinery in the process of using the wheel rim and track friction is an unavoidable phenomenon. This often produces the Ken rail will accelerate the wear of the wheel rim and wheel scrap, but also the track will produce serious wear. The use of rimless wheels can solve this problem, in the process of running crane machinery is easy to derail, so the use of the range is easily limited, in the use of the process must be used in conjunction with the horizontal wheel to prevent derailment. No rim wheel crane machinery in the running process to use the horizontal wheel guide running instead of rim guide running, the rim and track side sliding friction into the horizontal wheel and track side rolling friction, reducing the resistance to run thus improving the service life of the wheel.

Crane wheel and crane rail hardness

The service life of lifting machinery and the hardness of the wheel has a close relationship, from the form of damage to the wheels of lifting machinery, there are generally two kinds: one is fatigue spalling, the other is wear damage. The former is due to excessive hardness, hardening depth is not enough due to. In recent years, with the continuous improvement of the heat treatment process, the necessary depth of hardness can be met, so the fatigue spalling damage form has been very rare, wear damage has become the main form of wheel damage. Although the wheel hardness is too high, it will lead to early wear of the wheel track, especially the wheel rim and the wheel track between the sliding friction, the wear of the track will be more serious. In the process of use when the wheel and track wear cause damage, people prefer to replace the wheel rather than change the track. This is because replacing the track will cause long downtime and affect the production schedule. But the wheel hardness is too low, in the use of the process will accelerate the speed of wheel wear, and will appear rupture damage phenomenon, causing lifting machinery operation in the process of derailment of major safety accident potential, so the wheel hardness and the thickness of the wheel rim to become an important indicator to judge the quality of the wheel.

Cause analysis

The installation of crane machinery supervision and inspection process through the production and installation of the unit of discussion and communication I found that the reason for the phenomenon of low wheel hardness mainly exists for the following reasons.

First, some crane machinery wheel manufacturers use ductile iron to manufacture crane wheels, and stress the ductile iron mechanical properties, although the hardness is low, but in the use of small vibration, low noise and can meet the requirements of lifting equipment working conditions. But in the process of use, users find that there are often crane wheel rim tearing phenomenon, in order to better explain the cause of this accident, now we elaborate the analysis of ductile iron from the perspective of metal materials, ductile iron matrix organization is distributed with spherical graphite, due to the spherical graphite on the matrix organization of the role of cutting and stress concentration is very small, so the mechanical properties of ductile iron is much higher than The more rounded, small and uniform the graphite spheres are, the higher the mechanical properties are, and in some aspects they are even comparable to carbon steel. Ductile iron also has the shock absorption and wear resistance of gray cast iron. Ductile iron is obtained by spheroidizing the iron in the production process, i.e. adding a small amount of spheroidizing agent before pouring the iron to make the graphite spherical. At present, we commonly use three kinds of spheroidizing agents: magnesium, rare-earth alloys and rare-earth magnesium alloys.

The test results show that the yield ratio and wear resistance of ductile iron are better than 45 steel, and the elongation and modulus of elasticity after break are lower than 45 steel. However, due to the small sensitivity of the notch, the yield value of its specimen with shoulder strap hole is similar to that of 45 steel, and the impact toughness steel value of ductile iron is lower than that of 45 steel, and the life span is longer than that of 45 steel when working under the impact load condition of small energy. Therefore, because ductile iron has such excellent performance, it can successfully replace many malleable cast iron and medium carbon cast steel and forged steel materials in many occasions. However, complete replacement has not been achieved yet, the reason is that the plasticity and elasticity of ductile cast iron is lower compared to steel. After different heat treatments in production, such as annealing, normalizing, modulating treatment and isothermal quenching, ductile iron can obtain different matrix organizations: ferrite, pearlite + ferrite, pearlite and bainite. Through different heat treatment processes in order to change the internal metallographic structure of ductile iron, in order to obtain products that meet the requirements of mechanical properties.

Secondly, in the process of parts production and manufacturing, the production enterprises in order to reduce costs. The process of heat treatment of the product is artificially omitted. Crane wheel manufacturing specification GB/T6392-2008 clearly requires that any processing method of manufacturing wheels should be internal stress relief treatment. Cast steel wheels are annealed to eliminate internal stress before machining, don't and should be cleared of sand, cut pouring and risers, and checked for quality defects. The wheel rim should be surface quenched and fine-tuned before quenching. After heat treatment, the hardness of the tread surface and the inner side of the wheel rim should be satisfied with HB300-380.

Solution

First, the use of the unit should pay sufficient attention to the quality of lifting machinery parts, the use of the unit in the order contract with the supplier, the supplier should provide the product and the quality of each component to put forward certain requirements, in the case of reasonable product prices, in order to pursue the maximum degree of cost-effective.

Second, the inspector in the monitoring process, in strict accordance with the requirements of the inspection procedures for the lifting machinery wheel tread and rim of the inner hardness test. Use hardness tester in the wheel tread along the circumference of the equal measurement of three points, of which two points qualified that is qualified. When the hardness value of a test point does not meet the requirements, along the axis direction of the point plus the measurement of two points, such as the two points qualified that is qualified. In the process of wheel inspection, our lifting equipment inspectors not only to measure the hardness of the wheel, not to mention the quality of the wheel and manufacturing materials to review the certificate of conformity, the ability to use qualified metal materials and the correct manufacturing process and heat treatment process to ensure that the quality of the wheels of crane machinery qualified.

Comprehensive analysis of the above paper through the analysis of lifting equipment wheel manufacturing materials and processes, on the use of lifting equipment due to low hardness of the wheel caused by the accident potential danger, hope to cause the use of lifting machinery units, manufacturing units pay attention to, so as to protect the safe operation of lifting equipment in the use of the process.