In the construction of power plants, overhead cranes are a widely used lifting equipment. Its frequent use, large workload, vibration, and thus a high failure rate, bringing many adverse effects to the construction. Bridge crane electrical system and the commissioning process, scientific and reasonable construction methods are the key to ensure the quality of the system. Overhead crane electrical equipment installation and wire laying, should be strictly in accordance with the attached electrical schematic diagram, wiring diagram, electrical equipment general diagram and the corresponding standards.

Preliminary work before installation

Before the installation of overhead cranes and electrical equipment, should be specifically understand the relevant electrical diagrams and technical conditions, to understand the interaction of the components and operating principles, in order to quickly deal with the problems arising from the installation and commissioning. Before installation should be organized and view all electrical equipment and components. All electrical equipment and components should be free of shortcomings, work should be flexible, do not allow the phenomenon of stuck and loosened. The type of electrical equipment and components, standards, contact closure sequence, etc. must be in accordance with the drawings.

1.Motor

First of all, make a general appearance check, roll the coupling to observe whether the rotor is rolling flexible, and use megohm meter to measure its insulation resistance. If the stator is more than 1.5 megohm and the rotor is more than 0.8 megohm, it can be used, otherwise it should be dried. Drying method can be installed into the oven, but also can be passed into the low-voltage short-circuit current.

2. Solenoid

Installation need to check whether the moving part is loose, skewed or stuck phenomenon, and should be removed from the moving part and the magnet touch surface rust and other dirt. Magnet operation should not have open space between its touching surface, if there is necessary to adjust, eradicate the open space.

3. Linkage operating table or manipulator

The contacts of the combined surface should be line touch, pressure according to the contact size of about 10 ~ 17 Newton, the nut by the compression taut spring to adjust. The wiring screws should be tightened, touch should be outstanding. The operating handle should be flexible, and the gear should be obvious.

4. Resistor

The wiring of the resistor must be connected correctly according to the supplied information. If it is found that the motor is not powerful enough, the control handle can not lift the rated load or start the big and small car in the regular position. The first thing to check is whether the resistor wiring is wrong. For the organization of double motor drive, the resistor used should be properly selected and adjusted. The resistor with larger resistance value should be used for the motor closer to the operation room, or for the motor with "-" slip tolerance.

Resistor installation

Resistors with four boxes and less than four boxes can be directly stacked together. The resistors above four boxes should be installed on the resistor frame with 80mm interval between the boxes, and the heat insulation plate can be added in the middle to reduce the temperature rise of the uppermost resistor.

The placement of the resistor rack should take into account the ease of access and replacement of resistor components and facilitate heat dissipation. The channel in front of the rack should be no less than 600 mm, and the interval between the resistor element and the wall and floor should be no less than 150 mm.

Resistors should be placed along the direction parallel to the main beam, the resistor frame should be installed solidly, try to lap on the large tension bars of the walking platform to cut the chatter generated by the crane operation, if necessary, the upper end of the shelf can be added to the pull plate, one end of the pull plate can be welded to the steel structure.

Maintenance box and control box installation

The maintenance box and control box should be installed before the components and electrical wiring for detailed inspection. Components should not be damaged, especially the toucher interrupter cover and auxiliary contacts. Line insulation resistance should be in line with the requirements of the relevant regulations. Check whether the action of the time relay is in line with the rectification value required by the product factory technical documents.

Lifting control box time relay calibration value: 1SJ for 0.6 seconds, 2SJ for 0.2 seconds, 3SJ for 0.6 seconds, 4SJ for 0.3 seconds. The channel in front of the control is not smaller than 600 mm. The manipulation box should be installed sturdy and reliable, try to reduce the chatter that occurs in the operation of the crane, and add support if necessary, and the deviation of the screen surface from the straight surface should not exceed 5 degrees.

Installation of limit switches

Limit switch is an important device to ensure that no major equipment and personal accidents occur in the operation of the crane, the device should be carefully checked before the switch is flexible and reliable. Adjustment should be made one by one after installation. The distance between the large and small car limit switch and the collision rule should be adjusted appropriately, too tight will damage the switch, not to maintain the effect. The two limit switches of the hoisting mechanism should be adjusted separately. When the hook reaches the limit height, the heavy hammer type limit switch should be disconnected first, while the rotary type limit switch can be disconnected at a higher position, but the limit height should not be exceeded at this moment.

The device of the big car conductor

The operating surface of the conductive slide wire must be lubricated and clean, and the insulator of the big car conductor must be intact and without cracks, and be reliably fixed on the conductive frame. The conductor must be tightly pressed on the conductive sliding line, such as the operation of the spark that is poor touch, the reason may be the conductor and conductive sliding line touch is not tight or the operating surface is not clean, or both.

Usually in order to ensure safety, the operating room is generally installed on the opposite side of the trolley conductive slide, if necessary installed on the same side, should add a protective net maintenance.

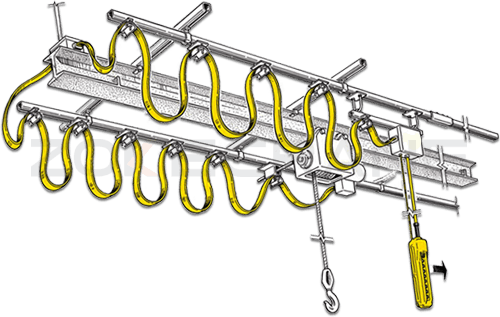

Trolley cable conductive device

Crane operating environment temperature of -25 ~ 45 ℃, the cable has CFR type marine rubber insulated neoprene sheathed flexible cable, the highest temperature is greater than 50 ℃, the cable with CEFR type marine ethylene propylene rubber insulated heat-resistant neoprene sheathed flexible cable. When the lowest temperature is -25℃, the cable has YHD type rubber insulated cold resistant rubber sheathed cable.

The installation should first straighten the cable, eliminate the torque, and arrange it on the knotted clip, cable trolley and dragging trolley in order according to the requirements of the drawing. Push the trolley to the limit of one end of the operating room, so that the cable release, adjust the orientation of the cable trailer, so that the length of each section of the cable is consistent and adhere to a certain degree of Chi, sagging angle adhere to about 120 °, adjusted, with the cable clamp will be firmly fixed to the cable end clamps and dragging carriage, and then push the trolley to the limit of one end of the operating room, adjust the cable, so that the hanging length of each section of the cable The cable is adjusted so that the overhang length of each section of the cable is basically the same, and the cable is fixed firmly on the cable carriage with the cable clamp. The cable is braided and clamped with iron every 500 to 700 mm.

Safety grounding

After the wire and wire pipe is laid, consider the safety grounding problem. Crane all charged parts of the shell, should be reliably grounded to avoid accidental electrocution accidents. Trolley rails are not welded to the main beam, should also take welding grounding, lighting transformer should be grounded in the low-voltage side according to the drawings.

The grounding wire should be galvanized flat iron with a cross section of not less than 75 square millimeters, 10 square millimeters of bare copper wire or 30 square millimeters of galvanized round steel. The grounding connection between the operation room and the crane body is 4×10 mm galvanized flat iron, and the connection should not be less than two. Grounding wire selection welding fixed, or choose the equipment on the grounding screw (galvanized), the joint should be cleared of rust stains, and the grounding wire painted black. The grounding resistance between any point on the crane to the neutral point of the power supply should not be greater than 4 ohms. A fuse should be provided on the crane or at the beginning of the power supply slidewire, and the rated current of its fusible piece should be 0.63 times the maximum current of the crane or power supply slidewire.