Jib Crane is a type of lifting equipment characterized by a cantilevered structure with a cantilevered boom as its main feature. It is widely used in various industrial fields for handling and lifting goods of different types and sizes.

Jib crane consists of the following main parts:

- Base: the base of a jib crane is the structure that supports and fixes the whole crane, which is usually fixed on the ground or other supporting structures.

- Jib (cantilever): the most distinctive feature of a jib crane is its cantilever structure, the jib is a horizontally extending boom, the length of which can be varied according to need.

- Hoisting mechanism: the hoisting mechanism is the component used to lift the goods, usually consists of winches, wire ropes or chains.

- Swivel mechanism: Some jib cranes have a swivel mechanism that allows the jib to rotate horizontally to cover a wider working range.

- Support structure: large jib cranes usually require a support structure to increase stability and load-carrying capacity.

Jib cranes are relatively simple to operate and are suitable for different sizes and types of cargo lifting needs. They are commonly used in industrial workshops, wharves, ports, construction sites, manufacturing industries and other places to provide efficient and flexible cargo handling solutions. The tonnage range of jib cranes varies from a few hundred kilograms for light cranes to tens of tons or even hundreds of tons for large cranes, which can meet the needs of a variety of different projects.

Floor Mounted Jib Crane

Floor mounted Jib Crane is a lifting equipment characterized by a unique structural design in which the supporting boom stands on a column. It is suitable for a variety of industrial areas for handling and lifting different types and sizes of goods.

Tonnage

The tonnage range of a column jib crane is usually small, generally around 0.5 tons to 10 tons. This makes it suitable for small and medium-sized cargo lifting needs.

Applicable environment

- Floor mounted Jib Cranes are suitable for the following environments:

- Indoor industrial sites: Luffing jib cranes are commonly used in workshops, warehouses and other indoor sites to provide efficient handling solutions for light and medium-sized goods.

- Construction sites: In construction sites, luffing jib cranes can be used to lift building materials, steel bars and other small goods.

- Assembly line: In the manufacturing industry, luffing jib cranes can be used for small assembly and handling operations on the assembly line.

Advantages

- Small footprint: the compact structure of the vertical column jib crane and the column support on the ground, the footprint is relatively small, suitable for places with limited space.

- High flexibility: due to the design of the floor mounted of the vertical column jib crane, its rotation and lifting operation is very flexible, and can cover a large working range.

- Easy to assemble: Column Jib Cranes are usually assembled in units, which makes installation and disassembly relatively simple and easy to relocate and adjust.

- Easy maintenance: due to the simple structure of the column jib crane, maintenance and repair is relatively easy, reducing maintenance costs.

Disadvantages

- Carrying capacity limitations: the carrying capacity of the vertical column jib crane is relatively small, suitable for small and medium-sized goods lifting, can not meet the needs of large-scale goods.

- Height limitation: the height of the column of the vertical column jib crane has certain limitations, which limits its lifting height, and is not suitable for large height operations.

- Not applicable to harsh environments: vertical jib cranes are subject to harsh environmental conditions (such as high temperature, corrosion, etc.) under the influence of the possibility of performance degradation, so you need to choose the right model according to the actual situation.

The vertical column jib crane is a lifting equipment suitable for small and medium-sized goods lifting. Its advantages of small footprint, high flexibility and easy assembly make it perform well in some specific environments. However, due to its limited load carrying capacity and restrictions on height and environmental conditions, it needs to be selected with comprehensive consideration of the actual needs and working environment.

Wall Mounted Jib Crane

Wall-mounted Jib Crane is a lifting device characterized by a jib and support structure (column) fixed to the wall, forming a cantilever structure suspended above the wall. It is used in various industrial fields for handling and lifting small and medium-sized goods.

Tonnage

The tonnage range of wall jib cranes is usually from 0.25 tons to about 5 tons. This makes it suitable for small and medium-sized cargo lifting needs.

Applicable environment

- Wall Jib Cranes are suitable for the following environments:

- Indoor industrial places: wall jib cranes are commonly used in workshops, production lines and other indoor places, especially where space is limited.

- Assembly line: In the manufacturing industry, wall mounted jib cranes can be used for small assembly and handling operations on the assembly line.

- Workshop: it can also be used for small and medium-sized goods handling in the workshop.

Advantages

- Small footprint: the support structure of wall jib cranes is fixed on the wall and does not require additional column support, so it occupies less floor space and is suitable for places with limited space.

- High flexibility: the jib and support structure are fixed on the wall, which makes the crane's rotation and lifting operation very flexible and can cover a large working area.

- Easy to assemble: wall mounted jib cranes are usually unit assembled, relatively simple to install and dismantle, easy to relocate and adjust.

- Easy maintenance: due to the simple structure, maintenance and repair is relatively easy, reducing maintenance costs.

Disadvantages

- Limited carrying capacity: the carrying capacity of wall jib cranes is relatively small, suitable for small and medium-sized goods lifting, not for large goods.

- Height limitation: the height of the column of the wall jib crane is limited, restricting its lifting height, not applicable to large height operations.

- Not applicable to harsh environments: wall jib cranes are subject to harsh environmental conditions (such as high temperature, corrosion, etc.) under the influence of the possibility of performance degradation, so you need to choose the right model according to the actual situation.

Wall jib cranes are a kind of lifting equipment suitable for lifting small and medium-sized goods. Its small footprint, high flexibility, easy assembly and other advantages make it perform well in some specific environments. However, due to its limited carrying capacity as well as restrictions on height and environmental conditions, it needs to be selected with comprehensive consideration of the actual needs and working environment.

Wall Traveling Jib Crane

Wall-traveling Jib Crane is a kind of lifting equipment, it is a kind of jib crane, the support structure (column) is fixed on the wall, at the same time, the jib is also equipped with electric or manual traveling mechanism, so that the whole crane can travel along the wall to cover a wider range of work. Wall traveling jib cranes are suitable for a variety of industrial sites for handling and lifting small and medium-sized goods.

Tonnage

The tonnage range of wall-mounted jib cranes is usually around 1 to 5 tons. This makes it suitable for small and medium-sized cargo lifting needs.

Applicable environment

- Wall-mounted jib cranes are suitable for the following environments:

- Indoor industrial places: Wall-mounted jib cranes are usually used in indoor places such as workshops and production lines, especially in places with limited space.

- Assembly line: In the manufacturing industry, wall-mounted jib cranes can be used for small assembly and handling operations on the assembly line.

- Workshop: it can also be used for small and medium-sized cargo handling in the workshop.

Advantages

- Small footprint: the support structure of wall-mounted jib cranes is fixed on the wall and travels along the wall without the need for additional column support, so it takes up less floor space and is suitable for places with limited space.

- Walking flexibility: wall-mounted jib cranes are equipped with a walking mechanism that can walk along the wall to cover a wider working area with high flexibility.

- Independent lifting and traveling operation: the lifting and traveling operations of wall-mounted jib cranes can be carried out independently, and the lifting and traveling operations can be controlled separately according to the actual demand, which improves the operation efficiency.

- Convenient maintenance: due to the relatively simple structure, maintenance and repair is relatively convenient, reducing maintenance costs.

Disadvantages

- Limited carrying capacity: the carrying capacity of wall traveling jib cranes is relatively small, suitable for small and medium-sized goods lifting, not for large goods.

- Height restriction: wall-mounted jib cranes have a limited column height, which restricts their lifting height and is not suitable for large height operations.

- Not applicable to harsh environments: wall-mounted jib cranes are subject to harsh environmental conditions (such as high temperature, corrosion, etc.) under the influence of the possibility of performance degradation, so you need to choose the right model according to the actual situation.

Wall traveling jib cranes are a kind of lifting equipment suitable for small and medium-sized goods lifting, with the advantages of small footprint, flexible traveling, lifting and traveling operations independently. However, due to its limited carrying capacity as well as the limitations of height and environmental conditions, it is necessary to consider the actual needs and working environment when choosing.

Container Jib Crane

Container Jib Crane is a kind of lifting equipment specially used for container loading and unloading in ports and other places. It is different from ordinary jib cranes in structure, mainly used for container loading and unloading operations.

Tonnage

Container jib cranes usually have a large range of tonnage, ranging from 30 tons to 100 tons. This makes it able to adapt to the loading and unloading of large containers.

Applicable environment

- Container jib cranes are suitable for the following environments:

- Ports and terminals: Container jib cranes are the main equipment for loading and unloading containers in ports.

- Ship loading and unloading: Container jib cranes can be used for container loading and unloading operations on ships to realize fast and efficient loading and unloading process.

Advantages

- High load-bearing capacity: container jib cranes have a large load-bearing capacity, and can cope with the loading and unloading needs of large containers.

- Efficient and fast: container jib cranes can quickly load and unload containers, improve loading and unloading efficiency, shorten the operating time.

- Flexibility: the jib of the container jib crane can be rotated to adapt to different positions of the loading and unloading operations, improve operational flexibility.

- Multifunctional: in addition to loading and unloading containers, container jib cranes can also be used for loading and unloading other goods, providing a variety of uses.

Disadvantages

- Higher initial investment: due to the large size of the container jib crane, its acquisition and installation costs are relatively high.

- Maintenance costs: container jib cranes require regular maintenance and repair to ensure their safe and reliable operation, which will bring certain maintenance costs.

- Restricted scope of application: container jib cranes are mainly used in ports and terminals and other places for loading and unloading containers, and their use is subject to certain restrictions.

Container jib cranes are a kind of lifting equipment specially used for container loading and unloading in ports and other places, which has the advantages of high carrying capacity, high efficiency and speed, flexibility and multi-functionality. However, its initial investment is high as well as the maintenance cost is large, need to consider the actual demand and economic factors when choosing. For ports and other places where a large number of containers need to be loaded and unloaded, container jib cranes are very important and necessary equipment.

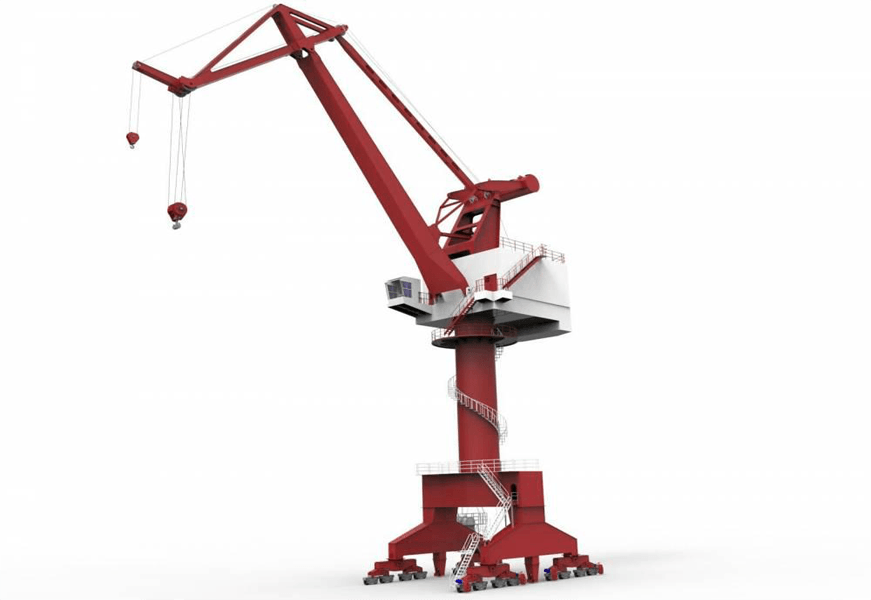

Portal Jib Crane

Portal Jib Crane is a lifting equipment, its structure is similar to a trestle bridge, with a column and a beam composed of the support structure. There is a cantilever suspended from the crossbeam, and the hoisting mechanism and lifting device are fixed on the cantilever, forming a cantilever structure suspended between the column and the crossbeam. Trestle jib cranes are suitable for large industrial places for handling and lifting medium and large goods.

Tonnage

The tonnage range of trestle jib cranes is large, from 50 tons to more than 1,000 tons. This makes it suitable for large cargo lifting needs.

Applicable environment

- Trestle Jib Cranes are suitable for the following environments:

- Large industrial sites: trestle jib cranes are usually used in large industrial sites, such as ports, steel mills, shipyards, etc., for lifting large cargoes.

- Elevated stacking sites: Because trestle jib cranes have a large tonnage and height, they are suitable for elevated stacking sites and can carry out high stacking operations.

Advantages

- High load carrying capacity: trestle jib cranes have very high load carrying capacity and can cope with the lifting needs of large goods.

- Large operating range: the crossbeam support structure of the trestle jib crane makes it have a large operating range and can cover a wide working area.

- Flexibility: The jib of the trestle jib crane can be rotated, and can be lifted and traveled to improve operational flexibility.

- Multifunctional: in addition to handling and lifting goods, trestle jib cranes can also be used for loading and unloading containers and other purposes.

Disadvantages

- Higher initial investment: due to the large scale of the trestle jib crane, its acquisition and installation costs are relatively high.

- Maintenance costs: trestle jib cranes require regular maintenance and repair to ensure their safe and reliable operation, which will bring certain maintenance costs.

- Large footprint: due to its large structure, trestle jib cranes need to occupy a large amount of ground space, the applicable environment has certain requirements.

Trestle jib crane is a kind of lifting equipment suitable for large industrial places, with the advantages of high load capacity, large operating range, flexibility and multi-functionality. However, its high initial investment, large maintenance costs and the need for a large footprint require comprehensive consideration of the actual needs and economic factors when choosing. For places where large cargoes need to be handled or high level stacking operations are carried out, trestle jib cranes are very important and necessary equipment.

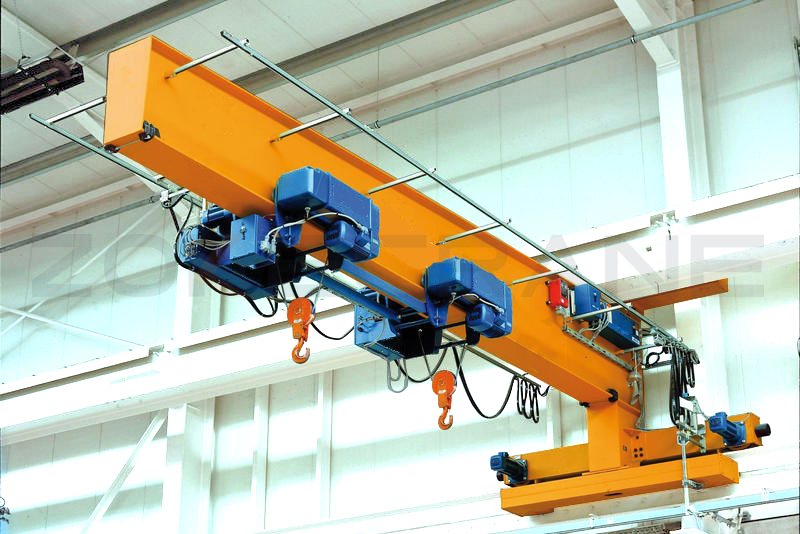

Difference between Jib Crane and Overhead Crane

Jib Crane and Overhead Crane are two common lifting equipments, which are very different in structure, working principle and applicable scenarios.

Structure difference:

- Jib Crane: Jib Crane consists of a support structure (column or wall) and a spanning support structure (cantilever), and the hoisting mechanism and lifting device are fixed on the cantilever. The working range of a jib crane is mainly realized by the rotation and lifting of the jib.

- Bridge Crane: A bridge crane consists of a pair of support bridges (bridges) spanning the working area between support structures (columns or walls). The hoisting mechanism and lifting devices span the bridges and cover the work area by traveling along the bridge tracks.

Difference in working principle:

- Jib Crane: The jib of a jib crane can be rotated and lifted for operation. Through the rotation and lifting angle of the jib, the lifting device is positioned to the required working position to complete the lifting task.

- Overhead Crane: The lifting mechanism and lifting device of the overhead crane can travel horizontally along the bridge track, and lift and carry goods through the lifting operation, and the working range can cover the whole area under the bridge.

Applicable scene difference:

- Jib Cranes: Jib cranes are suitable for small and medium-sized cargo lifting needs, and are usually used in indoor industrial places, such as workshops, warehouses, assembly lines and other space-constrained places.

- Overhead Crane: Overhead cranes are suitable for a variety of locations, and can be used for handling and lifting goods of different sizes and weights, and are suitable for both indoor and outdoor industrial locations.

Jib cranes and overhead cranes are two different types of lifting equipment. The working range of jib cranes is mainly realized by the rotation and lifting of the jib, which is suitable for the lifting needs of small and medium-sized goods. While the bridge crane through the walking along the bridge track and lifting operation to achieve the coverage of the working range, applicable to a variety of places and different scales of cargo lifting needs. Choosing the right lifting equipment takes into account the actual lifting needs, working environment and budget.

Difference between Jib Crane and Gantry Crane

Jib Cranes and Gantry Cranes are two different types of lifting equipment, which have significant differences in structure, working principle and applicable scenarios.

The structure is different:

- Jib Crane: Jib Crane consists of a support structure (column or wall) and a spanning support structure (cantilever), the hoisting mechanism and lifting device is fixed on the cantilever. The working range of the jib crane is mainly realized by the rotation and lifting of the jib.

- Gantry Crane: Gantry Crane consists of two columns and a spanning support structure (girder), the hoisting mechanism and lifting device spanning the girder. The working range of gantry cranes is mainly realized by lifting and traversing operations.

The working principle is different:

- Jib crane: the jib of jib crane can be rotated and lifted operation, through the rotation and lifting angle of the jib, the lifting device will be positioned to the required working position to complete the lifting task.

- Gantry Crane: The lifting mechanism and lifting device of gantry crane can travel horizontally along the track of the beam, and lift and carry goods through the lifting operation, and the working range can cover the whole area under the beam.

The applicable scenes are different:

- Jib cranes: Jib cranes are suitable for small and medium-sized cargo lifting needs, and are usually used in indoor industrial places, such as workshops, warehouses, assembly lines and other space-constrained places.

- Gantry cranes: gantry cranes are applicable to a variety of places, usually used in outdoor industrial places, such as harbors, freight yards, steel mills, etc., and are applicable to the lifting needs of large-sized goods.

Jib cranes and gantry cranes are two different types of lifting equipment. The working range of jib cranes is mainly realized through the rotation and lifting of the jib, which is suitable for small and medium-sized goods lifting needs, usually used in indoor industrial places. While the gantry crane through the lifting and traversing operation to achieve the coverage of the working range, applicable to the lifting needs of large-sized goods, usually used in outdoor industrial premises. Choosing the right lifting equipment takes into account the actual lifting needs, working environment and budget.